charpy v-notch impact testing|charpy impact test sample dimensions : traders This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test . Jogue com responsabilidade e divirta-se em jogoman | Cassino Online, jogos de cassino online que ganha dinheiro real. Copyright © 2019-2023 Jogoman. All rights reserved.

{plog:ftitle_list}

17 de mai. de 2001 · 《All Rise》是 Blue 演唱的歌曲,收录于2001年发行的专辑《All Rise》中。 [1] 中文名. 全体肃立. 外文名. All Rise. 所属专辑. All Rise. 歌曲时长. 0时03分43秒. 歌曲原唱. Blue. 音乐风格. 流行. R&B. 发行日期. 2001年5月17日. 歌曲语言. 英语. 歌曲歌词. yo,yo. your honour please. gotta believe what i say (say) what I will tell (tell) happened .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture.

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures. Learn more about the .

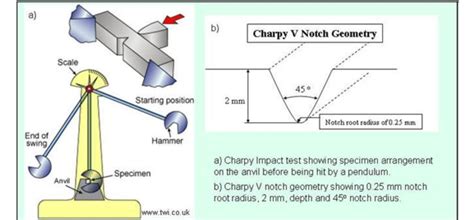

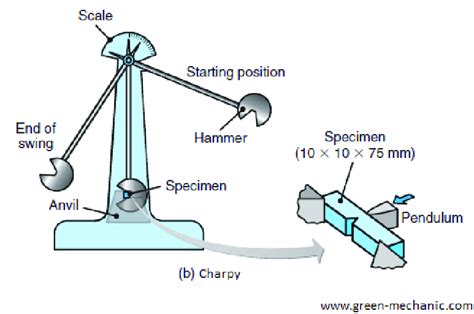

The Charpy specimen may be used with one of three different types of notch, a 'keyhole', a 'U' and a 'V'. The keyhole and U-notch are used for the testing of brittle materials such as cast iron and for the testing of plastics. The V-notch .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample. To successfully perform a Charpy V-notch impact test, the following steps must be followed for accurate results: 1. Notch test specimens. The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar.

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).A Charpy impact test, also known as the Charpy V-notch test, is a destructive method designed to measure the amount of energy that a material can absorb as it fractures. Understanding this helps to predict how the material will react to impact loading and is, therefore, an essential determining factor when assessing if your material is suitable .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces. 7 Recommendations for specifying impact strength requirements in steel specifications. The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized sample with a V-notch machined into it. . to calculate the impact energy in J/m2 by dividing the joule value by the sample's . Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance withFor the assessment of material toughness, international standards commonly require Charpy V-notch (CVN) impact testing of the steel product. A required toughness level is commonly expressed for a particular test temperature (which may be different to the lowest anticipated service temperature) at which a minimum CVN impact energy value (KV min .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve?As was written, toughness can be measured by the Charpy test or the Izod test.These two standardized impact tests, the Charpy and the Izod are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used.

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and materials development. EQUIPMENT • Charpy V-notch test specimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steelThis page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D . Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat. The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm.

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .

charpy v notch testing standard

Filler metals undergo rigorous testing to ensure they provide proper impact toughness to endure rapid loading, extreme temperatures or other stressors. The C.Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base. Updated by Reginald Davey 22/09/23. Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test.ESIS TC5, “Proposed Standard Method for Instrumented Impact Testing of Sub-Size Charpy V-Notch Specimens of Steels” (Annex C), Draft 10a, 23/5/02 [10] Lucon E., Round-Robin On Instrumented Impact Testing Of Sub Size Charpy-V Specimens: Results Of Phase 1”, ESIS TC5 Instrumented Impact Testing, Final Report, 2 April 1998 [11]

The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer.

The Charpy V notch test, or Charpy impact test, measures the energy absorbed by a material during fracture. The destructive test method consists of a pendulum, hammer, and a beam of metal placed between two anvils. The energy required to fracture the material provides insight into the material’s notch toughness at various temperatures.One of the main differences from Charpy impact is that Izod impact testing is performed in two orientations on the same sample whereas the Charpy test is performed in the same orientation. Plastic samples are typically a 64 x 12.7 x 3.2 mm bar with a machined V-shaped notch.

minimum pipe wall thickness for ultrasonic testing

Resultado da 菲尔‧艾维 (Phil Ivey)强者归来,线上扑克王品牌形象大使!. Created with Sketch. 撲克王诚邀4大AV女神,化身性感荷官现场互动!. Created with Sketch. 扑克王成为Triton Poker豪客系列赛冠名赞助商. Created with Sketch. Tom Dwan正式签约成为扑克王形象大使.

charpy v-notch impact testing|charpy impact test sample dimensions